© 2015 All Right Reserved.

Design by AbacusDesk

Home / Quality / Case Studies

We at Rikki Plastic believe in delivering high quality Plastic products and maximizing Customer Satisfaction. Apart from the timely schedules, we also help customer reduce their cost and improve efficiencies at their end. Thus, we get into Value Analysis and Value Engineering processes with the customer and help them find creative alternatives to already running functions. Some of the VA/VE activities that we performed are mentioned below as Case Studies.

1. Metal to Plastic Conversion

A leading construction and agricultural equipment OEM wanted to convert two of their critical parts from metal to plastic. The parts were to be converted in such a way that they could withstand high impact and resist wear and tear.

Problem Statement

Rikki Plastic Pvt. Ltd. had to find the suitable plastic material, improve the part design and look for opportunities of process change to make the new part. It had to be taken into account that the cost and weight of the component goes down, however the quality and functionality of the component is not compromised.

Improvement Process

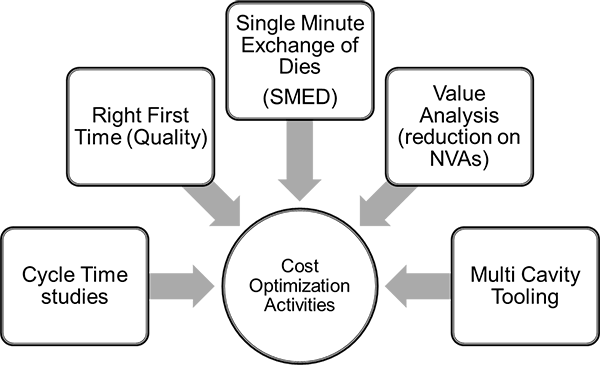

Rikki Plastic’s team worked closely with the customer to gather customer requirements and expectations. Different types of materials were reviewed and analyzed to check the impact and tolerance. Mould design and process details were also discussed with the customer. Trials were done for different materials, and field tested to see which material was to be used for production. Please refer to the graphic below to understand the different avenues of cost saving.

Solutions and Findings

Rikki Plastic’s proactiveness and expertise in plastic moulding help the OEM convert their metal parts to plastic. Not only the aesthetic and dimensional properties were enhanced, overall performance of the component was improved. Close collaboration with the customer helped Rikki Plastic to complete this project quickly and cost effectively. Rikki Plastic gave an approximately 60% cost saving on both the components.

2. Localization of Components

A construction equipment manufacturing company was importing some of its components from abroad and was not able to find suppliers to develop them in India

Problem Statement:

Rikki Plastic had to design the component in such way that it was cost effective as well as the quality is not compromised. The company incurred high cost in importing the components and wanted to source it locally. Finding the right quality components which could be supplied directly on line was a challenge for the company.

Improvement Process

Rikki Plastic Pvt. Ltd. focused on a four dimensional QCDF approach. QCDF stands for Quality, Cost, Delivery and Flexibility. Quality of the product delivered, minimizing the cost of the product delivered, delivering the product on time and be prepared for and unseen changes i.e. flexible in our approach.

For each of the parameters, Rikki plastic had one on one discussion with the customer, also conducted closed group meetings in-house. As these parts were majorly assembly parts, looking out for new suppliers for BOP parts was also a challenge.

Solutions and Findings

Rikki Plastic came up with the high quality assembly parts which were then supplied to the OEM. This led to approx. 50% cost saving for the OEM.