© 2015 All Right Reserved.

Design by AbacusDesk

Home / Engineering / Tool Room

We at Rikki Plastic determine our success by our ability to maximize the success of our customers- and for injection moulded plastics, we understand that tool design and mould engineering is critical to achieving that success.

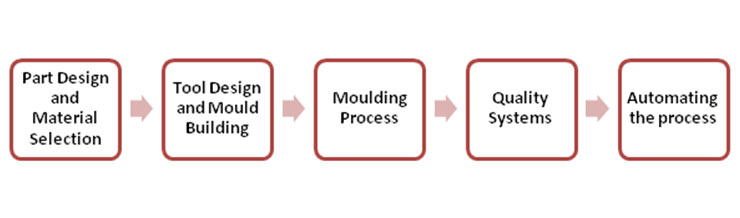

We understand that there are 5 key stages that need to work together to achieve success.

Tool Design should understand the end product application, its intended performance objectives and the market requirement of the product. Focus should be given on the tool life, efficiency and performance. We also make sure that the proper maintenance of the tool is done so that the part quality is not compromised

We at Rikki Plastic Pvt. Ltd. believe in working with, rather working for, the customer. Our design teams partner with the design teams of the OEM at an early stage of the part development. Hence, we are able to minimize the cost for our customers and bring in value.

Some of the machines in our Tool room are listed below:

| Srl. NO. |

M/C DESCRIPTION | MAKE | YEAR OF PURCHASE | CAPACITY |

| 1. | Milling Machine | Precicut Taiwan | 2000 | 1000 x 450 x 120 |

| 2. | E.D.M. | M/s Electronica Plastic Machine Pvt. Ltd. | 2003 | 35 / 55/ 50 Amp. |

| 3. | E.D.M. | Ratna Parkhi | 2016 | 35 / 55/ 50 Amp |

| 4. | Lathe Machine | J.J.C. Delhi | 2004 | 3' x 200 mm |

| 5. | Lathe Machine 6' | J.J.C. Delhi | 1997 | 3' x 200 mm |

| 6. | Surface Grinder | Guru Machine Tools | 1997 | 315 x 200 x 200 mm |

| 7. | Surface Grinder | Guru Machine Tools | 1999 | 315 x 200 x 200 mm |

| 8. | Drill Machine | Turn O MEch Engrs. Rajkot . | 1997 | 20 mm |

| 9. | E.D.M. | Electronica Plastic Machine Pvt. Ltd. | 2006 | 25 Amp. |

| 10. | Milling Machine | Precicut Taiwan | 2006 | 1000 x 450 x 120 |